PTFE Bellows

Bellows can perform a variety of tasks in a mechanical system, including vibration dampening, absorption of displacement in a piping system, compensating for misplacement and misalignment, and the protection of brittle components (glass, graphite, glass-lined steel, etc.).

When PTFE is used for bellows, their applicability expands greatly.

CHEMICAL RESISTIVITY

PTFE bellows are ideal for corrosive and chemically aggressive environments because of PTFE’s outstanding chemical compatibility.

EASE OF SANITATION

There is another reason why you see PTFE bellows used in the chemical, pharmaceutical, food, and diary industries: PTFE is far easier to clean up than other polymers because its chemical nature repels liquids and other materials from the surface. It is also resistant to the harshest of cleaning regimens, including high-temperature and/or steam sanitization.

MECHANICAL PROPERTIES

In addition, PTFE bellows have a long flex life and a very durable, making them ideal for critical applications involving dangerous chemicals – which is one of the reasons why they are popular for use in pollution control applications. PTFE bellows are also commonly used to provide shielding for highly sterile areas.

Its low flex makes PTFE very well adapted to protecting sensitive, brittle equipment from excessive vibration, misalignment, or displacement. Furthermore, PTFE bellows are often used in conjunction with piping systems (including lined pipes), metering devices, and valves (such as stem valves, aseptic valves, sampling valves, servo valves, solenoid valves, etc.).

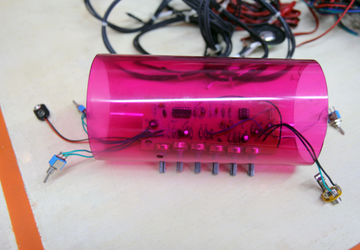

ANTI-STATIC GRADES

PTFE bellows are available in static-dissipating/anti-static grades for very sensitive applications, making them a first choice for many semiconductor manufacturing systems or areas where static build-up can become a serious issue.

Related Industries: