ETCHED PTFE Products

Etched PTFE is a type of polytetrafluoroethylene (PTFE) that has been etched, or chemically treated, to create a roughened surface. This roughened surface can increase the material’s adhesion properties, making it useful in applications such as gasketing, sealing, and coatings.

Etched PTFE Products:-

Etched PTFE is available in a variety of forms, including sheets, tubes, rods, and shapes. The type of etched PTFE used depends on the application and the desired properties.

- Etched sheets: Etched sheets are the most common form of etched PTFE. They are used in many applications, including gaskets and liners.

- Etched tubes: Etched tubes are used for applications such as fuel lines, cable insulation, and air lines.

- Etched rods: Etched rods are used in applications such as valve guides, bearings, and seals.

- Etched shapes: Etched shapes are used in applications such as electrical connectors, brackets, and flanges.

Advantages:-

Etched PTFE has a variety of benefits, making it a highly sought-after material for many industries. Here are some of the benefits of etched PTFE:

- Chemical Resistance: Etched PTFE has excellent chemical resistance, making it ideal for use in chemical processing plants and other harsh environments.

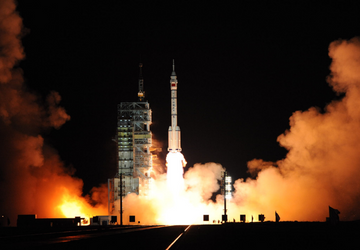

- Thermal Stability: Etched PTFE is able to withstand high temperatures, making it suitable for applications such as heat exchangers and nuclear reactors.

- Low Coefficient of Friction: The etched surface of PTFE has a low coefficient of friction, making it ideal for use in bearings and other machinery.

- Non-Stick: The low friction of etched PTFE makes it ideal for use in non-stick coatings.

- High Strength and Durability: Etched PTFE is extremely strong and durable, making it suitable for use in high-stress applications.

- Low Cost: Etched PTFE is a cost-effective material, making it a popular choice for many applications.

Applications:-

Etched PTFE has a variety of applications across many industries. Here are some of the most common applications of etched PTFE:

- Gaskets and liners: Etched PTFE is often used as a gasket or liner material, as it can be bonded to other materials for a secure connection.

- Bearings: The low friction of etched PTFE makes it an ideal material for bearings, as it reduces wear and tear on the bearing.

- Fuel Lines: Etched PTFE is often used in fuel lines due to its chemical resistance and thermal stability.

- Valve guides: Etched PTFE is often used as a valve guide material, as it is resistant to wear and tear.

- Heat exchangers: Etched PTFE is ideal for use in heat exchangers due to its high thermal stability.

- Electrical connectors: Etched PTFE is often used in electrical connectors due to its low coefficient of friction and high durability.

PTFE Lip for Radial Shaft Seals:-

PTFE shaft seals are the perfect choice when it comes to sealing applications with demanding operational parameters. Using high performance fillers, our PTFE shaft seals are able to operate in environments that are too severe for elastomer solutions to be considered.

Applications with high peripheral speeds, high pressure and low friction, dry running or with an extended service requirement, are all ideal cases to specify a PTFE solution.

Mask Seals provides word class PTFE washers for this application with surface treatment by using Plasma Etching as well as conventional chemical etching as per customer requirement.

Mask seals provides washers from 0.25mm to 2mm in thickness.

Advantages:-

- Outstanding chemical resistance

- Broad temperature range -60⁰C to +200⁰C

- Suitable for low lube and dry running conditions

- High wear resistance of seal lip

- Special designs for low power losses

- Suitable for high speeds

- Low stick slip

Applications:-

- Rotary compressors

- Blowers

- Transmissions/gearboxes

- Pumps

- Mixers

- Centrifuges

- Dosing systems

Related Industries: